The intelligent equipment wave is sweeping through the manufacturing sector, reshaping production processes with industrial connectivity and digital twins; AI is deeply involved in precision assembly, meticulously controlling the manufacturing precision of core components; green intelligent manufacturing integrates photovoltaic power supply and circular technologies, propelling the industry towards a new era of carbon neutrality. These three innovations collectively drive the comprehensive upgrade of manufacturing.

At the critical juncture of intelligent manufacturing transformation, intelligent equipment, AI, and green technology are becoming the core drivers of breakthrough.

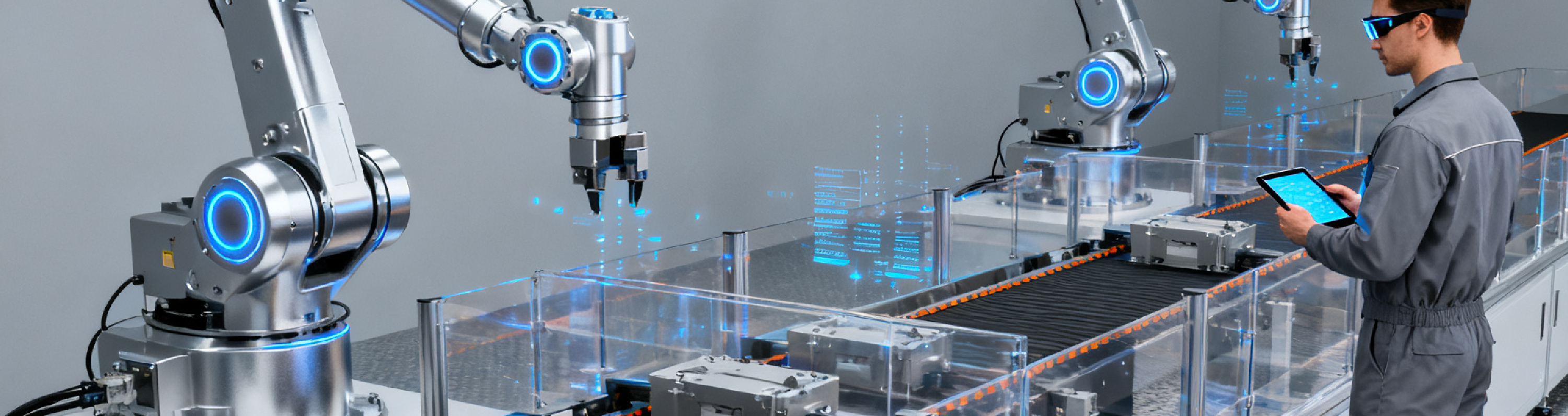

Intelligent equipment, leveraging industrial internet and digital twin technologies, enables real-time monitoring and dynamic optimization of the entire production process. From raw material intake to finished product rollout, every is infused with intelligent vitality. AI algorithms are deeply integrated into assembly processes. For precision components such as harmonic drive reducers, real-time data feedback and parameter adjustments enhance assembly accuracy to within ±0.005mm, pushing the product yield rate beyond 99.5% and effectively redefining the error standards of traditional manufacturing.

Green intelligent manufacturing, meanwhile, builds a sustainable production model through innovative technologies. Photovoltaic power supply systems inject clean energy into production lines, coupled with efficient waste recycling systems, reducing energy consumption by 30% and effectively cutting carbon emissions, thereby accelerating the industry's progress towards carbon neutrality goals. The synergistic force of these three elements not only reduces costs and enhances efficiency for enterprises but also propels manufacturing towards a high-quality development path characterized by intelligence, precision, and sustainability.